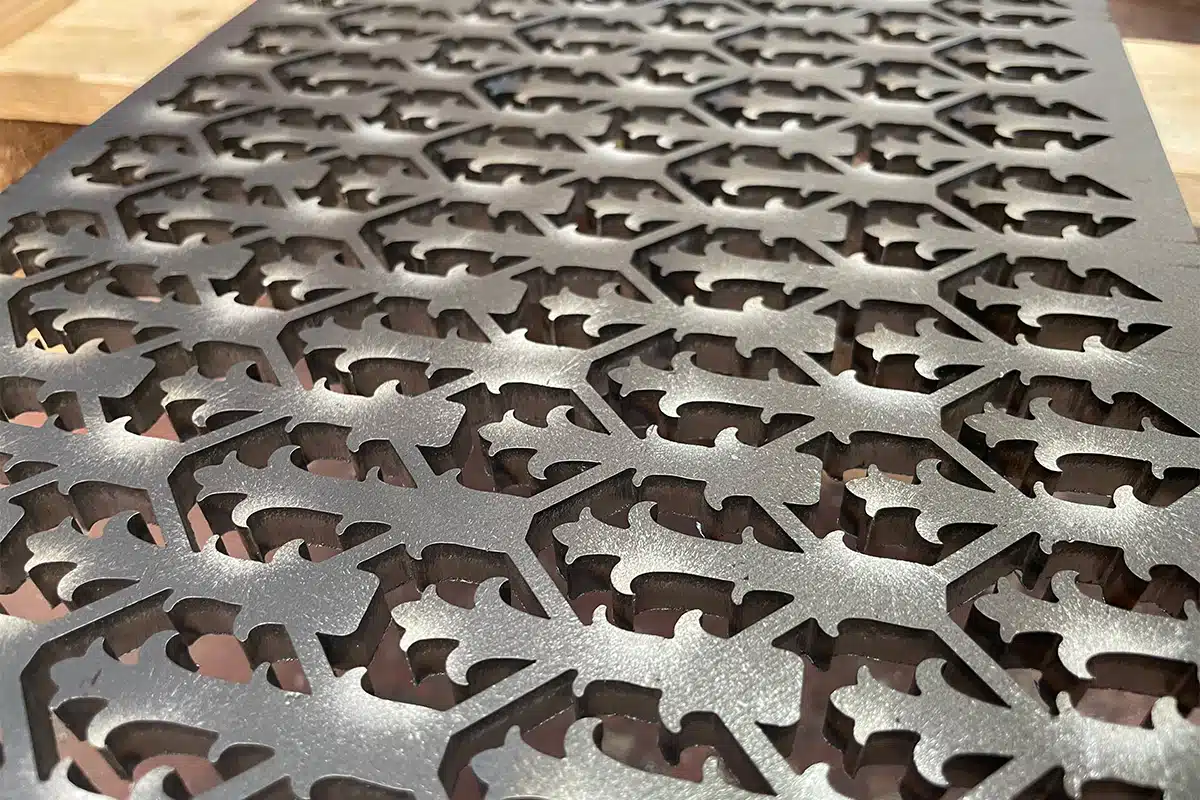

Sheet Metal Cutting

Sheet metal laser cutting is a precise and efficient industrial process that uses a high-powered laser beam to cut intricate shapes, designs, or patterns from flat sheets of metal. The laser beam melts, burns, or vaporizes the material, creating accurate cuts with minimal heat-affected zones.

Precision sheet metal laser cutting with rapid lead times from our high capacity, Sheffield-based production facility.

24-hour lights-out manufacturing across our comprehensive suite of laser cutting machines ensure even the largest projects receive a fast turnaround. Complemented by an in-house design team and end-to-end processing services, our sheet metal laser cutting is hard to beat.

CNC laser cutting technology guarantees absolute accuracy. Intricate cutting and fine contouring are achievable across a range of metals, including thin and thick mild steel. Eliminate additional process steps with the ability to produce chamfers and countersinks, in a single pass. Tighter nesting delivers a highly cost-effective laser cutting sheet metal service.

What Materials Can Be Flow Drilled?

Sizes range from M2 to M30 inc BSP sizes in material thicknesses from 0.5mm to 10mm with different material applications:

The following materials can all be used to FlowDrill:

- Mild Steel

- Stainless Steel

- Copper

- Brass

- Bronze